Understanding the Gravity Die Casting Process Professional

1 year ago - Services - Michigan City - 93 viewsGravity die casting is a commonly used method of castingwhereby a hallow mold is filled with molten metal under the forces of gravity.Unlike pressure die casting, where in external forces are applied to the moltenmetal to push it inside the mold, in gravity die casting, the molten metal isallowed to flow into the mold as a result of its own weight. This process ispopular in automotive and aerospace industries because it yields parts of goodmechanical properties of high dimensional and geometrical precision.

To know more about gravity die casting - https://www.indianmetal.solutions/

What is Gravity Die Casting?

In the gravity die casting process, molten metal isintroduced into a reusable metallic mold (referred to as die as well) viagravitational force. The mold is manufactured of steel or cast iron and is madefor multiple usages making the cost of the manufacturing process for medium tohigh quantity casting runs very economically efficient. Molds are manufacturedin a way that they are quite complicated geometrically and built with finedetails opening doors for mass production of accurate parts.

Benefits of Gravity Die Casting

Exceptional Quality of Castings

High quality gravity die casting services involve producinghigh quality castings with very high dimensional accuracy and surface quality.This means that it is appropriate for parts which have close fittings and needa fine finish.

Economical for Medium to Large Scale Production

The fabrication of a recoverable metal mold has a relativelyhigh initial cost, however as gravity die casting can be carried outrepeatedly, this makes it‘s cost beneficial for medium to large runs. Alsoreduces the amount of materials that are wasted when compared to other castingtechniques.

Improved Mechanical Properties

Parts achieved by gravity die casting are usually of bettermechanical properties than those attained through sand casting. Thesolidification process is enhanced through cooling, which increases the castcomponents mechanical strength and toughness.

Different Types of Materials

Gravity die casting can use various metals such as aluminum,or zinc and copper alloyed with magnesium. Each one presents a differentproperty magnifying the opportunity of the manufacturer to pick the right onefor the desired use.

Key Steps in the Gravity DieCasting Process

Preparation of the Mold

To achieve correct and continued flow of metals within themold, it is essential to preheat the mold before casting. The requiredtemperature depends on the alloy type being cast. Also, usually a core releaseagent is coated to the mold so as to reduce metal bonding and enhance thequality of the final product.

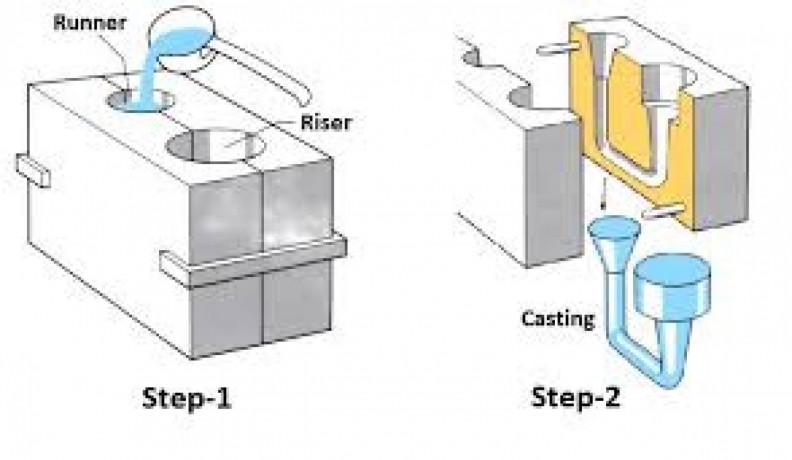

Pouring the Molten Metal

When the mold is ready, molten metal, aluminum alloys, zincalloys, or copper alloys usually contained in a ladle is poured into the moldcavity. The filling of the mold with the metal occurs purely through theactivity of highly accelerated gravity which effectively reaches every cornerof the mold’s geometry.

Solidification and Cooling

Casts are formed whenever the mold has been filled by themolten metal and the metal cools within the internal section of the mold. Thenew cast part can be susceptible to changes depending on the cooling speed, souniform cooling can be done to eradicate chances of deformities like shrinkageor even pores. After sufficient cooling processes have occurred until the metalis fully solidified, the mold is taken apart and the casting removed.

Finishing and Trimming

When the cast is taken from the mold any extra material suchas runners and risers will be cut off. Sometimes, it is also necessary to usesome finishing operation, for example, machining, polishing, heat treatment,etc. for the surface or mechanical properties of the final part.

Common Applications of Gravity Die Casting

• Automotive Industry

Gravity die casting technology is widely applied formanufacturing engine components, transmission cases, cylinder heads and otherstructural parts in the automobile industry. Because of this feature, it alsoallows increasing the general performance and reducing the fuel consumption ofthe automobile.

• Aerospace Industry

Components used in the aerospace industry are oftenfabricated using gravity die casting due to the strength to weight ratiorequired of aircraft engine parts, landing gear components and supportingstructures.

• Consumer Goods and Electronics

A large number of appliances and electronic devices containgravity die adjustable parts: light and strong aluminum covers and brackets.

Challenges of Gravity Die Casting

Limited to Simple Geometries

Even though gravity die casting may incorporate certaintechnological intricacies it isn’t quite as flexible when it comes to designingdetailed models with cut-outs as pressure die casting. More geometricallycomplex components may require secondary operation of machining or assemblyfollowing casting.

Initial Investments for Tooling May be Costly

The fabrication of intermediate and last metal dies andother reusable metal forms can be expensive which will discourage some lowerproduction runs. However, for medium to high volume batch production, it willbe cost effective because of the reusability of the molds.

Coming About the Risk of Shrinkage

Subsequent to the cooling down and solidification stages,the metal could possibly undergo shrinkage, which may compromise the dimensionsand cause some defects. Poor design of the molds and not controlling thecooling process effectively imposes risks of such nature.