Aluminum Casting: The Complete Process, Types and Uses ofAluminum Castings Professional

1 year ago - Services - Michigan City - 84 viewsAluminum casting is a plastic manufacturing process withbroad applications which result in the production of parts that are light butstrong. Aluminum casting finds applications in multiple industries includingautomotive, aerospace, construction and electronic, and as such has become anintegral part of modern manufacturing. This article examines the aluminumcasting process, its different techniques, benefits, as well as variousindustries which obtain aluminum castings and their application.

To know more about Aluminum Casting- https://www.indianmetal.solutions/

What is Aluminum Casting?

Aluminum casting is a controlled manufacturing processwhereby liquids of aluminum alloys are poured with the aid of gravity into amold whose dimensions and shapes have already been determined. It is aproductive manufacturing process that is characterized by precision tolerances,excellent surface finishes and is capable of producing a variety of intricateshapes. Aluminum has characteristics including, lightweight,corrosion-resistant, as well as a high strength-to-weight ratio, making it veryfit for casting especially for bear stress where low weight and high durabilityare of priority in industries.

The Aluminum Casting Process

The basic aluminumcasting process encompasses a number of steps which are as follows:

1. Design Steps of the Mold: The casting process commencesfrom designing the mold itself which determines the shape of the aluminum partto be produced. The design process encompasses the type of material, whichinclude steel, sand or ceramic from which the mold is made depending on the castingtechnique employed.

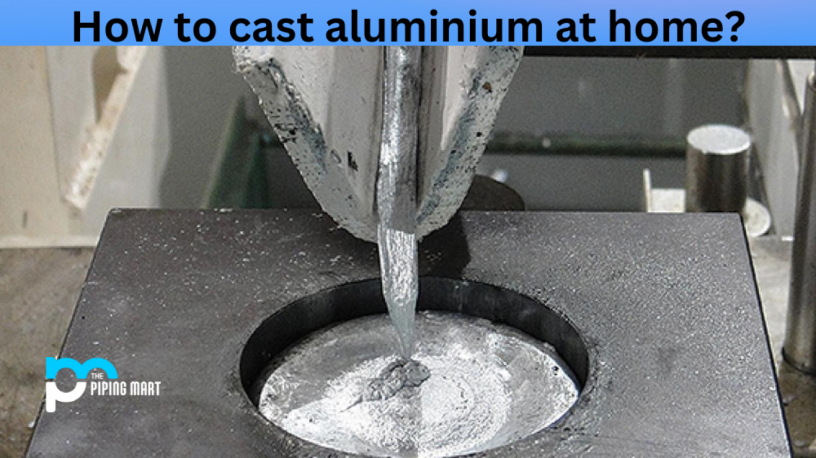

2. Gettingthe Aluminum to Melt: Applying heat in a furnace will melt aluminum since itsmelting point is approximately 660 °C (or 1220 °F). After that, it is in liquidform and is poured or injected into the already shaped mold.

3. Pouringor Injecting the Aluminum: Aluminum in melted form is poured into the properpouring cavity or high-pressure brings it close to the cavity depending on themethod used. The molten material fills each and every cavity in a liquid formand when it cools and solidifies, it retains the shape formed by the cavities.

4. Coolingand Solidifying: The solidifying molten aluminum comes in touch with the insidesurface of the mold which results in the cast component attaining its finalshape. Each part is harder and has been cooled at a different rate depending onthe casting material and the methods where one was used in making the molds.

5. TakingOut and Finishing the Cast: Once shot blasting is done successfully, the castaluminum part is carefully taken out of the mold. The leftover unnecessarymaterials are cut off, and other finishing processes like machining andpolishing are done to some parts to ensure that they comply to qualityrequirements.

Aluminum Casting Methods

Casting aluminum can be done with a particular methoddepending on the final results intended. Some of the most common methodsinclude the following:

1. Sand Casting

Sand casting includes the mixing of the aluminum productwith a sand and a binding agent in a mold that can be knocked off when thealuminum has cooled. It is one of the most versatile and cheapest terrainswhich can be used to create large or intricate shapes. Sand casting allows forthe mass production of engine blocks, parts for aerospace and components ofindustrial machines.

2. Die Casting

In die casting, aluminum is over injected into a steel dieunder pressure. This method is very productive and yields high-quality partswith ideal surface and dimensional characteristics. Die casting is useful inmass production and is thus adaptable to preparing parts such as enginehousing, enclosures for electronics and automotive parts.

3. Permanent Mold Casting

Permanent mold casting makes use of metal molds which arereused, the molds are mainly in steel or iron. The process requires the use ofgravity whenever molten aluminum is poured into the mold or an under lowpressure process. Parts created via this method exhibit a fine grain structureand greater mechanical properties, such as those used for automotive wheels,engine pistons and cylinder heads.

4. Investment Casting (Lost Wax Casting)

This process involves the use of a wax model of the part,covering the wax model with a ceramic material, known as investment casting orlost wax casting. This ceramic shell, once solidified, has the wax melted,creating a cavity for the aluminum. This technique allows the fabrication ofmolds for small, intricate or gentle parts like the aerospace and medicalinstruments with extreme accuracy.

5. Centrifugal Casting

This method involves the introduction of a rotating mold towhich molten aluminum is poured. The molten metal is pushed against the wallsof the mold by centrifugal force allowing high-strength, hollow parts to beformed. This method is highly suitable for the manufacture of pipes, tubes, andother cylindrical parts with high strength and durability.

Advantages of Aluminum Casting

Aluminum casting is relatively popular in the industries forits many advantages as seen below:

1. Strong and Lightweight: Due to its high strength toweight ratio, aluminum is most suitable for components since they need notcompromise on durability and weight across automotive and aerospaceapplications.

2. Corrosion Resistance: Aluminum naturally forms an oxidelayer that is protective, thus preventing corrosion from occurring. Thisquality makes aluminum useful in the manufacture of components that are used inoutdoor or marine applications where conditions can be harsh.